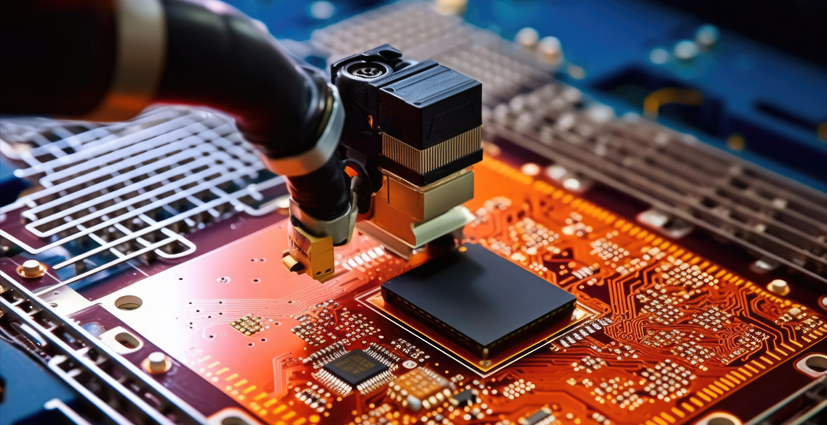

The global semiconductor industry is expanding rapidly and is expected to become a trillion-dollar industry by 2030. India aspires to be a major player in this growth, with its semiconductor market expected to reach USD 271.9 billion by 2032. To capitalise on this opportunity, the country has implemented generous fiscal support, conducive manufacturing policies, and international collaborations. However, setting up a semiconductor fabrication or assembly and testing unit in India requires navigating key considerations:

Regulatory approval

India permits 100% foreign direct investment for setting up a silicon / compound semiconductor fabrication unit, or an assembly, testing, marking and packaging (ATMP) facility, or an outsourced semiconductor assembly and testing (OSAT) facility without any government approval, except for investments from bordering countries.

Available Incentives

The central government has allocated INR 760 billion, providing up to 50% fiscal support for project costs, including capital expenditure / investment towards: (a) land, building, plant, machinery, clean rooms, equipment, and associated utilities; (b) research and development; and (c) transfer of technology.

Production Grade Technology

To qualify for government subsidies, applicants must demonstrate ownership or licensing of relevant production technology and a roadmap for advanced technology development.

Additionally, the applications are comprehensively evaluated on technological parameters and require a detailed technical project report.

Other Key Eligibility Conditions

The eligibility conditions vary from one GoI Scheme to another. For instance, setting up a silicon semiconductor fabrication unit requires a minimum capital investment of INR 200 billion, a minimum revenue of INR 75 billion in any of the three preceding financial years and an installed capacity of 40,000 WSPM or above with the wafer size of 300mm.

Offtake Commitments

Applicants must demonstrate offtake commitments covering up to 100% of the projected revenues, supported by binding documentation signed by potential customers.

Lock-in and Exit

The GoI Schemes contemplate a lock-in on the promoter for a period of 3 years from commencement of commercial production.

Project Location and State Level Support

The project location is crucial, with various states offering incentives based on the minimum investment level, employment generation and geographical location.

States like Gujarat, Tamil Nadu, Karnataka, Telangana, Uttar Pradesh, and Odisha provide fiscal and non-fiscal incentives such as land grants, utility exemptions, capex subsidies, and employment subsidies.

Conclusion

India’s aspiration to be the next global semiconductor manufacturing powerhouse is supported by robust incentive policies, initiatives for sustainable manufacturing (e.g., earmarking 20GW of energy for semiconductor fabrication), local manpower training programmes (through schemes like “Chips to Startup”) and improved logistics infrastructure.

However, setting up a semiconductor fabrication / testing facility is a capital-intensive and a technology driven activity, requiring extensive planning and preparation. Hence, it is essential to address issues such as technology transfer and off-take commitments to secure government support and navigate the approval process effectively.